In the realm of research and development, Walk-In Temperature & Humidity Test Rooms play a pivotal role across multiple sectors by simulating a range of environmental conditions. These facilities are crucial for testing and validating the endurance and functionality of products under variable climates. For instance, in the automotive industry, they assess vehicle components for thermal resistance and humidity effects, ensuring reliability and safety. Similarly, in pharmaceuticals, they are essential for stability tests on medications, determining shelf life under different atmospheric conditions. Exploring these applications further reveals how such testing capabilities are integral to advancing product reliability and enhancing industry standards. What might the implications be for future technological innovations and regulatory standards?

Walk-in temperature chambers are specialized environments designed to meticulously control and maintain specific temperature conditions. These chambers enable precise temperature regulation, crucial for environmental testing in various industries. By simulating a range of thermal conditions, from sub-zero to elevated temperatures, these units provide a versatile platform for assessing the performance and reliability of products under controlled thermal stress.

Constructed with insulated enclosures, these chambers are equipped with advanced temperature control systems that ensure uniformity and stability of the desired conditions. The ability to configure temperatures according to specific test protocols allows researchers and engineers to replicate environmental scenarios that a product might encounter during its lifecycle.

This controlled setting is essential for identifying potential failures and enhancing product designs to withstand unexpected temperature variations. Supporting fixtures within the chambers accommodate different sizes and types of test specimens, making them adaptable to a broad spectrum of testing needs.

The integration of such technology into developmental and quality assurance processes significantly enhances an organization's capability to develop products that are resilient, reliable, and conform to high standards of durability, thereby meeting or exceeding customer expectations.

Purpose-built to simulate specific humidity conditions, walk-in humidity chambers are essential tools for testing the effects of moisture on a variety of materials and products.

These chambers offer a controlled testing environment that meticulously regulates humidity levels, critical for assessing how materials withstand moisture over time. Walk-in humidity chambers are designed with advanced sensors and integrated systems that precisely control and maintain the desired humidity settings necessary for reliable testing outcomes.

Equipped to handle large-scale or multiple sample testing simultaneously, these chambers provide a stable environment for evaluating the durability, performance, and reliability of products under various humidity scenarios.

This capability is vital for industries like electronics, pharmaceuticals, textiles, and food, where humidity can significantly impact product quality and longevity.

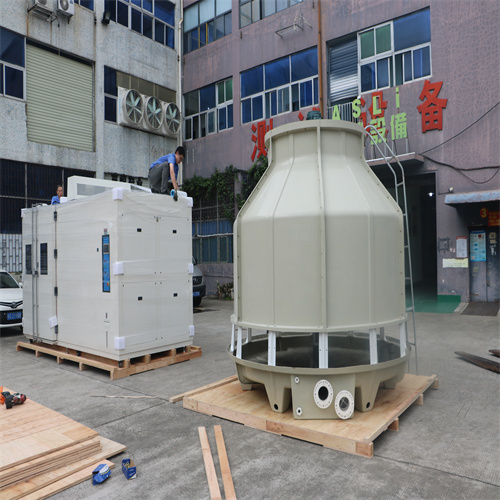

A walk-in temperature and humidity test room is a specialized type of climate-controlled chamber large enough to accommodate multiple test specimens or larger items.

This advanced facility operates on the principle of environmental simulation, replicating specific atmospheric conditions—temperature and relative humidity—to assess how materials or products perform under various climatic scenarios.

This form of testing is pivotal in verifying product quality, predicting service life, and determining the durability of a range of items from industrial components to consumer goods.

The walk-in design of these chambers provides a significant advantage by offering ample space, which allows for the testing of large-scale assemblies or simultaneous multiple tests, thereby enhancing operational efficiency and flexibility.

The core strength of these chambers lies in their capability to maintain homogeneous climate conditions throughout the space, ensuring consistency in testing protocols and results.

Temperature chambers designed for walk-in applications incorporate several critical features that ensure rigorous and precise environmental testing. One such feature is the broad temperature range these chambers offer, from as low as -70°C to as high as 150°C, enabling them to support extreme temperature calibration testing. This capability is essential for developing products that must withstand harsh environments.

Moreover, these chambers are designed with advanced airflow systems that promote uniform temperature distribution, critical for maintaining consistent conditions required for reliable test results. Such uniformity is vital for ensuring that all parts of the test sample are exposed to the same conditions simultaneously.

Stability is another hallmark of these chambers, with precise temperature control mechanisms that keep the internal environment within tight tolerances throughout the test duration. This stability is crucial for experiments where even minor temperature fluctuations could skew results.

Safety features are also paramount, including alarms, emergency stop buttons, and backup power supplies that safeguard both the testing process and the personnel involved.

Additionally, the flexibility of these chambers is enhanced by their customizable nature, allowing for the installation of shelves, racks, and ports. Robust chamber insulation is vital for maintaining desired conditions and energy efficiency.

To meet the stringent requirements of various industries, walk-in temperature chambers are employed extensively to simulate and evaluate the effects of extreme temperature conditions on a range of products. These chambers provide precise temperature control and humidity regulation, essential for assessing product reliability and performance under varied environmental stresses.

| Industry | Application | Importance |

|---|---|---|

| Automotive | Testing components like engines and batteries | Ensures durability and safety |

| Electronics | Assessing device functionality | Guarantees performance stability |

| Pharmaceutical | Stability testing of drugs and vaccines | Validates quality and efficacy |

In the automotive sector, the ability to control and maintain specific temperature conditions helps in evaluating the performance of critical components such as engines and batteries, which must withstand extreme conditions. Similarly, in the electronics industry, ensuring that devices operate efficiently across a range of temperatures is crucial for consumer reliability. For the pharmaceutical industry, walk-in temperature chambers are indispensable for stability testing, where precise temperature and humidity settings are crucial to determine the shelf-life and effectiveness of drugs and vaccines, ultimately ensuring compliance with global health standards.

Building on the capabilities of walk-in temperature chambers, their humidity counterparts offer equally vital functionalities for environmental testing. Walk-in humidity chambers excel in humidity control, capable of achieving a broad spectrum of humidity levels from low single-digit percentages to conditions of high humidity. This range is crucial for replicating varying real-world environments effectively.

A key feature of these chambers is their advanced dew point control. This technology enables precise regulation of the dew point, which is essential for accurate humidity measurements and to prevent unwanted condensation during tests. Such precision ensures that the environmental conditions within the chamber can be finely tuned to meet specific R&D requirements.

Moreover, these chambers are designed with uniformity in mind. Thanks to sophisticated air circulation systems and humidity distribution techniques, they maintain consistent humidity levels throughout the entire testing space. This uniformity is critical for ensuring reliable and repeatable test results.

Safety and reliability are also paramount, with walk-in humidity chambers featuring robust safety protocols, including backup systems and integrated humidity sensors. These measures safeguard against excessive moisture, which could damage test samples or impair chamber performance.

Additionally, customization options like adjustable shelves, rotating platforms, and various access ports allow for a highly adaptable testing environment, tailored to specific project needs.

Given their robust design and precise humidity control, walk-in humidity chambers are indispensable in various industrial and research applications.

These chambers play a crucial role in electronics testing, where they create conditions to assess how electronic components perform and resist corrosion in high humidity environments. This is vital for developing products that are durable and reliable under different climatic conditions.

In the packaging industry, walk-in humidity chambers are essential for evaluating the impact of humidity on packaging materials. Testing protocols ensure that adhesives and seals maintain their integrity, preventing moisture-related defects which can compromise product quality.

Similarly, in the textile industry, these chambers test materials for strength, dimensional stability, and resistance to mold and mildew, essential for ensuring that fabrics perform well in diverse environments.

Environmental testing also relies on these chambers to simulate various humid conditions to study the effects on different equipment and materials. This helps in predicting product lifespan and functionality in different climates.

Furthermore, in research and development sectors, walk-in humidity chambers provide a controlled environment to study the behavior of materials and biological samples, facilitating innovation and improvements in product design and material sciences.

Walk-in chambers are critical tools used across industries for environmental testing, product validation, and research. These chambers simulate a variety of conditions—temperature, humidity, pressure, and even gas levels—allowing companies to test products and materials in controlled environments. There are different types of walk-in chambers, each designed for specific testing needs. In this article, we’ll explore the main types of walk-in chambers, helping you understand which one might be right for your application.

A walk-in temperature chamber is designed to simulate a wide range of temperature conditions. It can be used to test how products, components, or materials react to extreme heat or cold. These chambers typically offer temperature control from -70°C to +180°C (or even higher, depending on the specific model).

Key Applications:

Features:

A walk-in humidity chamber is used to simulate and test high or low humidity conditions. These chambers provide an environment where humidity levels can be controlled and adjusted, usually within the range of 10% to 95% relative humidity. They’re often used for testing the impact of moisture on products, packaging, and materials.

Key Applications:

Features:

A walk-in temperature and humidity test room combines both temperature and humidity control in a single unit, allowing for more complex and comprehensive environmental testing. These chambers are versatile and can simulate various environmental conditions, from hot and dry to cold and wet, in a single space.

Key Applications:

Features:

Designed specifically for testing vehicles, this type of walk-in chamber simulates environmental conditions that vehicles might encounter during operation. This could include temperature extremes, humidity levels, and even rain or dust. It’s crucial for the automotive industry to ensure that vehicles, both internal components and exterior parts, perform optimally under various condition

Key Applications:

Features:

An artificial weather chamber replicates a variety of weather conditions, such as rain, snow, UV exposure, and extreme heat. This chamber is used to simulate the effects of environmental elements on materials and products over extended periods, similar to accelerated aging tests

Key Applications:

Features:

Low oxygen training chambers simulate conditions with low oxygen levels, often used in medical, aerospace, or military applications. These chambers create a controlled environment with oxygen concentrations as low as 12-16%, allowing users to train or test products under hypoxic conditions

Key Applications:

Features:

Stability test chambers are used primarily in the pharmaceutical and food industries to test the shelf life of products. These chambers simulate the temperature and humidity conditions that products might encounter during storage and shipping

Key Applications:

Features:

Each type of walk-in chamber serves a specific purpose and caters to different industries and applications. Whether you're testing electronics, packaging, automotive components, or pharmaceuticals, selecting the right walk-in chamber can significantly impact the accuracy and efficiency of your environmental testing. By understanding the different types and their unique features, you can make an informed decision to meet your testing requirements effectively.

Numerous industries rely on Walk-In Temperature & Humidity Test Rooms to ensure product quality and compliance with international standards. These chambers are crucial for conducting stability testing, a process integral to determining the shelf life and safety of products under specific environmental conditions.

In the pharmaceutical sector, these rooms facilitate ICH stability testing, where drugs are subjected to precise climate control to ascertain their expiration dates. Adherence to stringent guidelines like ICH Q1A (R2) and VICH GL3 is mandatory, and the ability of these chambers to quickly restore conditions after access is particularly valued.

In the food industry, accelerated shelf-life testing (ASLT) is employed to predict product longevity under various storage scenarios. Walk-in chambers simulate conditions such as varying temperatures and humidity levels, essential for assessing potential chemical, microbiological, and physical degradation over time.

Cosmetics also undergo rigorous stability testing within these controlled environments. The aim is to ensure that both the formulation and packaging withstand adverse conditions, thus guaranteeing the product's quality and safety throughout its intended shelf life.

Moreover, in life sciences and microbiology, these chambers provide the essential climate control necessary for cultivating bacteria, maintaining high humidity to prevent culture desiccation.

Walk-in Temperature & Humidity Test Rooms offer significant advantages to industries that require stringent environmental control.

These chambers excel in providing precise environmental conditions essential for reliable testing, ensuring testing accuracy across a wide range of temperature and humidity settings. Thanks to their block construction, they operate efficiently under all simulated conditions, enhancing energy efficiency and reducing operational costs.

The user-friendly control desk facilitates seamless operation with features that allow real-time data capture and automatic storage of test results. This not only streamlines the testing process but also ensures data is readily available for analysis, further boosting the efficiency and accuracy of research and development projects.

Additionally, the well-lit interior and clear multi-pane viewing windows aid in monitoring the test process without disrupting the environment, ensuring consistent results.

The robust security features, including multi-level access control and secure locking mechanisms, underscore the chambers' reliability and safety, protecting both the tests and the operators.

Customization options for Walk-in Temperature & Humidity Test Rooms allow industries to tailor features according to specific testing requirements and operational demands. The integration of custom features such as additional doors, including double swing doors, enhances accessibility and operational efficiency.

For specialized applications, the incorporation of a refrigerator for heat load adjustments or a frost-free expansion system can be critical in maintaining low humidity levels.

Design flexibility is further evident with options like full-ceiling air ducts for uniform air distribution or airflow adjusters that allow precise control over environmental conditions. Facilities that handle sensitive or large-scale materials might opt for a loading ramp or a preparation room to streamline the testing process.

For enhanced testing accuracy in temperature and humidity chambers, auxiliary humidifiers and water purifiers ensure optimal condition control.

Safety and maintenance aspects are not overlooked, with features like flow switches for water-cooled models and exhaust air ducts tailored to indoor air-cooled specifications.

Each component, from entrance curtains to thermocouples, is selectable to craft a highly functional and responsive environment that meets the exacting standards of rigorous R&D activities.

How do you determine which walk-in temperature and humidity test room is best suited for your specific needs? Choosing the right room involves a critical evaluation of several factors that ensure precise temperature control and effective humidity regulation.

Start by assessing the specific requirements of your application, such as the range of temperature and humidity needed, the size of the items being tested, and the expected test durations.

Consider the capacity for customization. A system that offers flexible control settings allows for adjustments to be made according to varying research demands. This adaptability is crucial for applications that may evolve over time or require stringent environmental conditions.

Next, evaluate the technology and reliability of the system. Opt for models that feature advanced technology capable of providing consistent and accurate environmental conditions. Reliable systems reduce the risk of test interruptions, which can be costly and time-consuming.

Lastly, factor in scalability. As your research expands, you might need to increase the capacity of the test room. Choose a room that can be easily upgraded or has the potential to integrate additional modules to accommodate growing needs.

To ensure optimal performance and longevity of walk-in temperature and humidity test rooms, regular maintenance and diligent care are imperative. Adherence to detailed operational guidelines and systematic maintenance can prevent system malfunctions and ensure consistent results.

Here are essential practices that must be integrated into the routine care of these chambers:

Implementing these guidelines will help in the effective management and preservation of walk-in temperature and humidity test rooms.

Energy costs for operating walk-in test rooms vary widely. A detailed cost analysis focusing on energy efficiency is crucial to optimize expenditures. Strategic planning can significantly control and reduce long-term operational costs.

Yes, walk-in test rooms effectively simulate outdoor weather conditions for climate simulation and environmental testing, offering precise control over temperature and humidity to ensure accurate and reproducible testing conditions.

Walk-in test rooms typically have a lifespan of 10 to 15 years, contingent on rigorous maintenance. Regular upkeep ensures optimal performance, crucial for those requiring precise environmental control in research and development settings.

Walk-in test rooms are fortresses of safety, equipped with features adhering to strict safety regulations. These include emergency exits, fire suppression systems, and alarms, ensuring compliance with critical emergency protocols for user protection.

In conclusion, walk-in temperature and humidity test rooms are quintessential in the tapestry of modern R&D, weaving reliability and precision into the fabric of product innovation. Their ability to simulate a multitude of environmental conditions ensures that only the most robust and effective products stand the test of time. As the saying goes, "Necessity is the mother of invention," and in the realm of research and development, these chambers are indeed indispensable.

Founded in 1988, ASLI (China) Test Equipment Co., Ltd. produces high-quality inspection instruments and testing equipment, including temperature and humidity chambers, aging testers, and vibration testers. Certified to international standards, ASLI serves research, quality inspection, and educational sectors worldwide, renowned for precision, reliability, and exceptional customer service.

Contact us for a free quote of your ideal walk in temperature humidity test chamber!

[…] evaluate the Temperature & Humidity Range necessary for your testing. Standard chambers offer ranges from -40°C to +180°C and 10% to 95% […]